FAM is the first commercialized silicone 3D printing technology

FAM stands for Fluid Additive Manufacturing, specially developed for printing heat-curing silicone, RTV silicone, and LSR silicone.

San Draw

Advanced Silicone 3D Printing Solutions

Interview with San Draw: Insights into Advanced Silicone 3D Printing Technology

Oct 10, 2024

San Draw’s Fluid Additive Manufacturing (FAM) technology is a patented silicone 3D printing process designed for high-precision manufacturing with RTV and LSR silicone materials.

This specialized process enables high-precision 3D printing with RTV and LSR silicone materials, supporting biocompatible, heat-resistant, and flexible components. FAM unlocks new applications in soft material additive manufacturing, including simulation models, wearable devices, robotics, and industrial parts.

Unveils the World's Leading Commercial

Two-Part 3D Printed Silicone

Mar 14, 2025

San Draw’s patented Fluid Additive Manufacturing (FAM) technology enhances silicone 3D printing by enabling high-precision manufacturing with RTV, LSR, and heat-curing silicone materials.

FAM ensures stable quality and control for flexible, biocompatible, and heat-resistant parts. S180 printer supports applications from simulation models and wearables to soft robotics and industrial components.

Fluid Additive Manufacturing Research for Silicone 3D Printing

Feb 25, 2022

A Parametric Study for Tensile Properties of Silicone Rubber Specimen Using the Bowden-Type Silicone Printer

This study examines the tensile properties of silicone rubber printed with a Bowden-type 3D printer using the Taguchi method. Key printing parameters were analyzed to optimize strength and flexibility. Findings offer insights to enhance silicone additive manufacturing for applications like soft robotics and wearables.

Keywords: parametric study; taguchi method; tensile properties

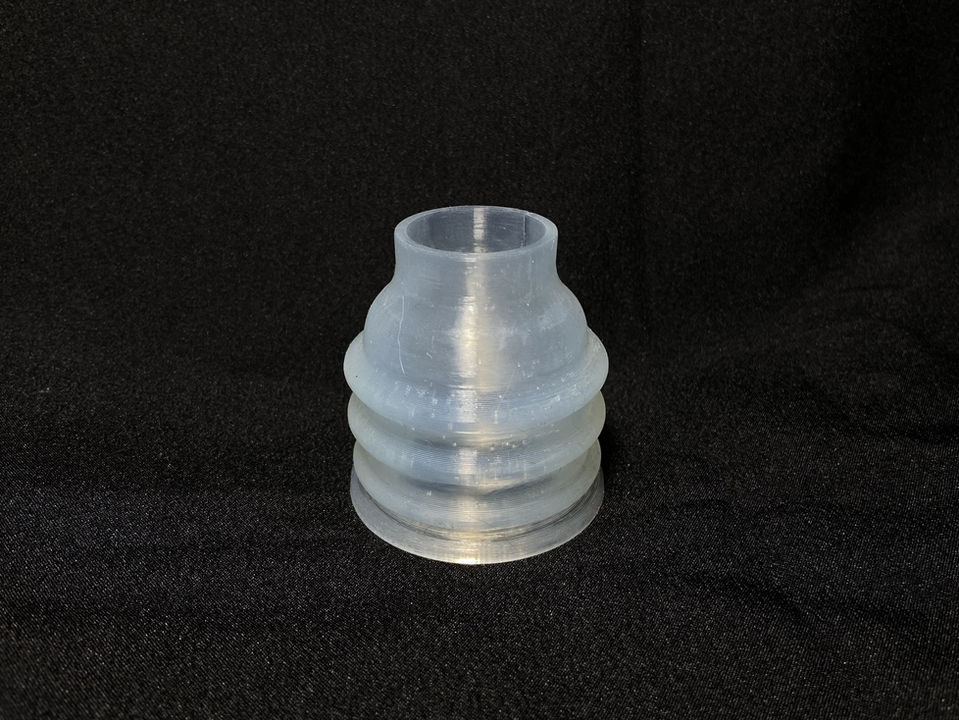

Silicone Pneumatic Grippers

Silicone Material : SIL18 (Shore A 18)

Silicone pneumatic grippers made with SIL18 (Shore A 18) offer a soft and flexible solution for handling fragile or irregular objects. This ultra-soft silicone material features low hardness and a skin-like texture, making it especially suitable for applications that require a gentle and adaptive grip.

When combined with pneumatic control, the gripper adjusts to complex shapes while maintaining low surface pressure. It is well suited for soft robotics, wearable technology, and biomedical simulation where precision and consistency are important.

Silicone 3D Printing Materials

SP65 Water-Soluble Support Materials

SP65 is a water-soluble support material designed for silicone 3D printing with RTV and LSR materials. It enables the creation of complex, thin-walled, and free-form structures by providing temporary support during printing.

After fabrication, SP65 dissolves easily in water—leaving clean silicone parts without manual post-processing. Ideal for applications like soft robotics, simulation models, and wearable components, SP65 expands the design freedom of silicone additive manufacturing.

.png)

.png)